VirtualPaint

IWRC Development of VirtualPaint Training System

In the mid-2000’s, the IWRC recognized there could be a way to make spray painter training more efficient utilizing virtual reality technology. It was along this basis in 2004 that we developed the idea for the first version of the VirtualPaint system.

Officially released in 2006, VirtualPaint became the first virtual reality system for spray application training, developed by painter training experts. VirtualPaint was created for one purpose, to provide an interactive solution to the challenge of spray technician training by using computer simulation to simplify the training process and provide spray technicians with precise non-biased feedback of their performance through various forms of visual and statistical feedback that cannot be easily replicated in a spray booth.

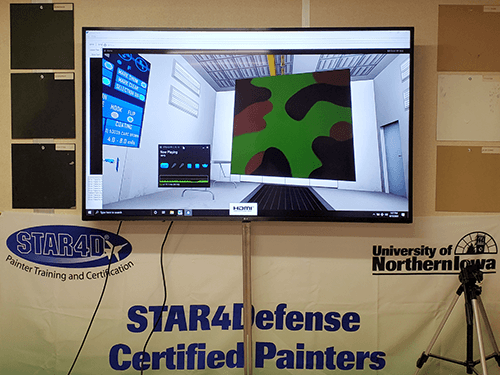

STAR4D use of 3D VirtualPaint Training and Results

Since VirtualPaint uses no real coatings or parts, the cost to train an employee can be minimized during the training process as the student can practice over and over again until perfecting skills. As an added benefit virtual training does not require the traditional PPE to be worn making it a safer training environment.

Integration of new technology into training is also recommended whenever possible. The VirtualPaint 3D training system reduces the amount of time that it takes to train an artisan. The training helps artisans develop and improve paint skills including gun speed, movement, distance and pattern overlap. Since the system is 3D the artisan can practice on complex parts with inside/out corners, protrusions and curved surfaces. Since VirtualPaint does not use actual real coatings or parts, costs associated with training can be minimized.

The system tracks real time metrics including material sprayed, transfer efficiency, coating cost, time, and amount of trigger pull which can be used to track artisan fatigue. VirtualPaint can also track wet and dry film thickness, and consistency of film thickness which is a key inspection criteria that the artisan will be responsible for achieving on production items. VirtualPaint includes a database with time and date stamp which can be used to track students’ performance and any improvement over time.

Documented cost savings of over 15% was observed in a 2023 report: Evaluation of Methods to Deliver Surface Preparation and Painter Training at DoD Depots.

As of July 2018, management and sales of the VirtualPaint training system was transferred to VirtualPaint Products, LLC. The VirtualPaint system is covered by U.S. Patent Nos. 7,839,416, which is owned by the University of Northern Iowa Research Foundation and licensed exclusively to VirtualPaint Products, LLC.