Industrial Painter Training

For a customized quote, contact us

Sample Itineraries

Case Study

Omega Cabinetry, a division of MasterBrand Cabinets, Inc. needed painters to be trained in order to meet the annual training requirement of the wood furniture NESHAP (40 CFR 63, Subpart JJ). IWRC developed a one-day customized course to meet the specific requirements of the regulation. Click below to read the case study.

The importance of painter training cannot be undersold. A workforce of trained painters can improve productivity, reduce rework and defects, decrease air emissions and hazardous waste generation and even meet and exceed regulatory compliance.

IWRC’s trainers have worked with small businesses and Fortune 500 companies alike within a wide array of industries including aerospace, defense, auto body, metal manufacturing, and woodworking.

Every business faces different challenges; IWRC Painter Training provides a variety of training options for businesses to utilize. Ranging from a half day to multiple day trainings, IWRC’s trainers will provide customized training to meet your facility’s needs.

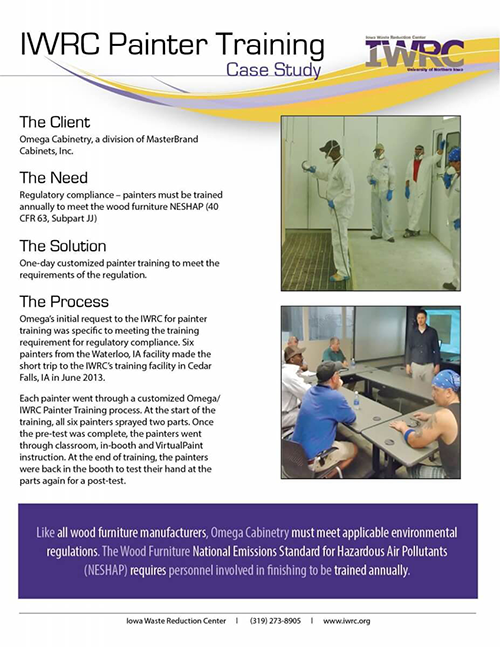

- Classroom Training

Through classroom training, our trainers teach your painters the fundamentals of coating operations through interactive presentations, demonstrations and use cutting edge technology such as the VirtualPaint 3D virtual reality paint simulator. Our trainers develop customized training curriculum based on the needs of the facility.

Topics Covered (see sample itineraries in sidebar)

- Masking

- Surface preparation

- Liquid coating systems

- Coating defects and failures

- Spray equipment and setup

- Application technique and efficiency

- Cleaning and maintenance

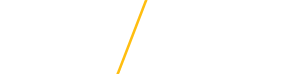

- In-Booth Training

IWRC’s trainers can work with your painters in-the-booth providing hands-on instruction with your spray equipment, liquid coatings and production parts.

Topics Covered

- Safety and proper PPE

- Spray equipment set up

- Proper spray technique (plan of attack)

- Mil thickness (wet/dry)

- Paint Line Observation

The IWRC’s painter trainers have over 20 years of experience in actual spray application. Through observing your facility’s paint line, our trainers can provide recommendations to improve the overall efficiency of your operations.

Recommendations Include

- Reduce rework costs

- Regulatory compliance

- Cleaning and maintenance issues

- Spray equipment selection

- Training Curriculum

Each training session is customized based on the needs of the facility dependent on types of equipment, coatings and processes used. Curriculum development has always been developed in-house at the IWRC. Some curriculum has been created for specific purposes.

- Surface coating operations (National Emission Standards for Hazardous Air Pollutants (Subpart HHHHHH): Paint Stripping and Miscellaneous Surface Coating Operations)

- Wood furniture manufacturing (Subpart JJ – National Emission Standards for Wood Furniture Manufacturing Operations)

Other curriculum has been developed for broad purposes such as STAR4D’s curriculum which covers chemical agent resistant coatings and aerospace coatings as well as curriculum developed for business and industry.